Paint protection film (PPF)

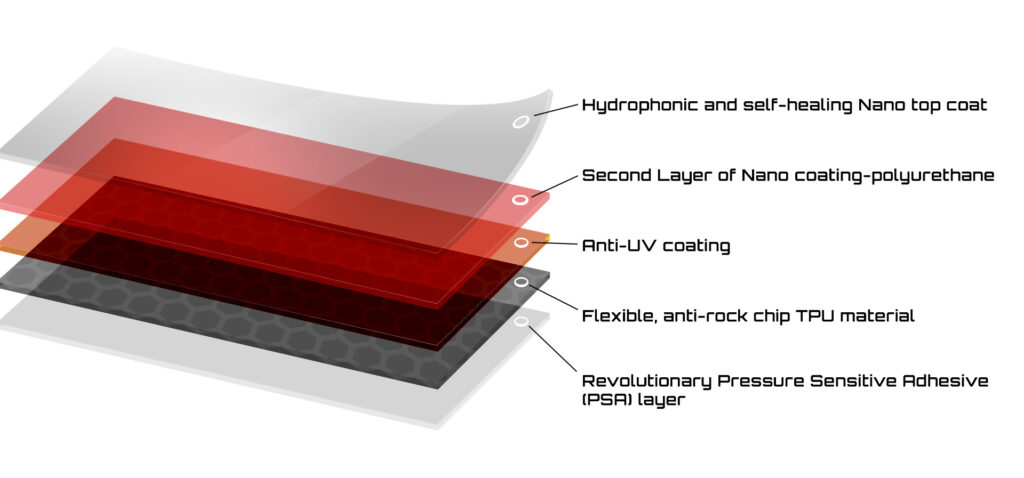

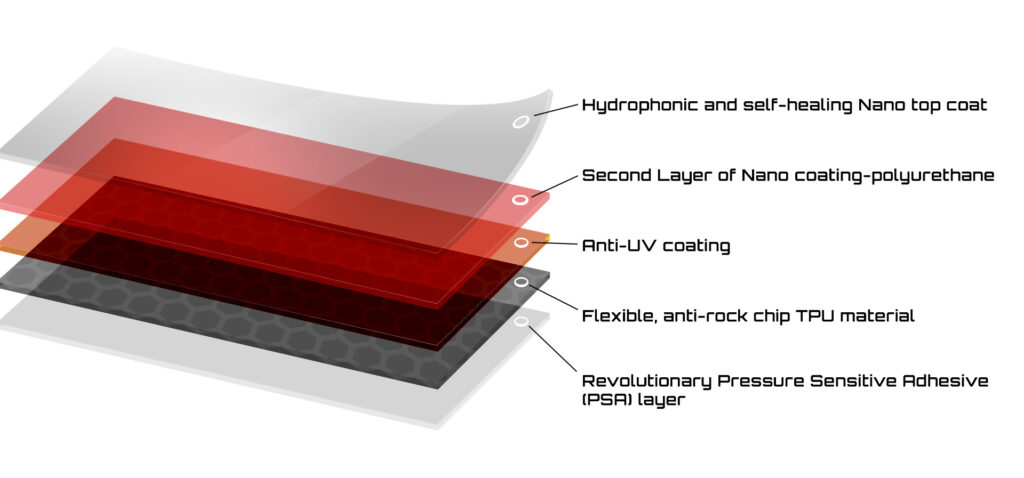

Also called clear bra, clear film, or clear paint film, is a thermoplastic urethane film often self-healing film applied to painted surfaces of a new or used car in order to protect the paint from stone chips, bug splatters, and minor abrasions. This film is also used on airplanes, RVs, cell phones, electronics, screens, motorcycles, and many other areas. Paint protection film is OEM approved by virtually all car manufacturers.This film is most commonly applied to high-impact areas of vehicles which include: the hood, the front fenders, the front bumper, the side view mirrors, the rocker panels, the lower portion of the doors, and the rear guards behind the rear wheels.

History of PPF

The roots of PPF can be traced back to the late 1950s when a thin, transparent layer was first used to protect the paint of aircraft bodies from UV sunlight. This innovative technology was a significant step forward in extending the lifespan and preserving the beauty of aircraft bodies.

PPF Enters the World of Racing

In the 1970s, PPF was used to protect the bodies of racing cars from gravel and minor impacts on racetracks. This transparent coating significantly prevented damage caused by contact with various objects at high speeds and helped maintain the performance and appearance of racing cars.

Military origins of paint protection film

As with many other consumer products, paint protection films were first developed and used by the military. During the Vietnam War, helicopter rotor blades and other sensitive parts of military transports were often damaged by flying shrapnel and debris. In order to help protect these moving parts, the US military asked 3M to come up with a solution that was both inconspicuous and low-weight.

The advantage of replaceable film over the replacement and repair of damaged rotor blades was immediately clear and its adoption was uncharacteristically quick for the US military. As a result, there are still people in the industry who refer to PPF as “helicopter tape” although this term is becoming less and less common as automotive applications have taken precedence.

Expansion of PPF to Personal Cars

Over time and with technological advancements, PPF made its way from the racing world to personal cars as well. In the 1980s, car owners were looking for ways to protect their car bodies from scratches, chemicals, and other harmful environmental factors. PPF emerged as an ideal solution for this purpose by offering numerous benefits.

Innovation and Diversity in PPF

Today, we witness a wide variety of PPF with unique features and benefits in the market. PPF manufacturers are constantly improving the quality and performance of this product using new materials and advanced technologies. Self-healing, water-resistant, and UV-resistant PPF are examples of recent innovations in this field.

PPF’s Role in the Modern World

In the modern world, where car beauty and health are of paramount importance, PPF is considered a necessity for many car owners. This protective coating not only safeguards the car body from various damages but also enhances its overall aesthetic appeal.

Applications of PPF

In addition to protecting car paint, PPF has other applications, including:

- Protecting the screens of smartphones and tablets: PPF can shield these devices’ screens from scratches, scuffs, and fingerprints.

- Safeguarding laptop bodies: PPF can protect laptop bodies from scratches, scuffs, and impacts.

- Protecting accessories: PPF can safeguard accessories like phone cases, laptop sleeves, and camera bags from scratches, scuffs, and wear.

Benefits of PPF

The advantages of using PPF include:

- Scratch protection: PPF protects the car body from scratches caused by gravel, tree branches, contact with hard surfaces, and even unwanted scratches by pets.

- Chemical resistance: Acid rain, bird droppings, road salt, and other corrosive chemicals are the arch-enemies of car paint and body. PPF creates an impenetrable shield, protecting the car body from these substances and preventing corrosion, erosion, and fading.

- Sunburn protection: Harmful UV rays from the sun are the primary culprits behind the gradual fading and dulling of car paint. PPF, by blocking these rays, safeguards the shine and brilliance of your car’s paint against the scorching sun, preserving its stunning beauty for years to come.

- Self-healing properties: Some advanced PPF types incorporate self-healing technology. This means that minor surface scratches will automatically disappear when warmed by sunlight or using a hairdryer, allowing you to enjoy your car’s flawless beauty without worrying about minor scratches.

- Increased car value: Maintaining the impeccable and gleaming appearance of your car’s body using PPF significantly enhances its value when it comes time to sell. Buyers seek cars that boast a healthy and new look.

Drawbacks of PPF

- Cost: Installing PPF can be relatively expensive, especially when done by a professional installer.

- Installation difficulty: PPF installation requires skill and experience, and if not done correctly, bubbles or wrinkles may appear on the film.

- Appearance: Some people may not prefer the look of PPF, as it can be slightly glossier than the car’s paint.

Tips for Choosing and Installing PPF

- PPF type: Various PPF types offer different features and benefits. Do your research and select a type that suits your needs and budget before making a choice.

- Installer: PPF should be installed by a professional installer. Don’t hesitate to ask about the installer’s experience and background and check their portfolio.

- Warranty: Ensure the installer provides a warranty for their work.

Types of installation available

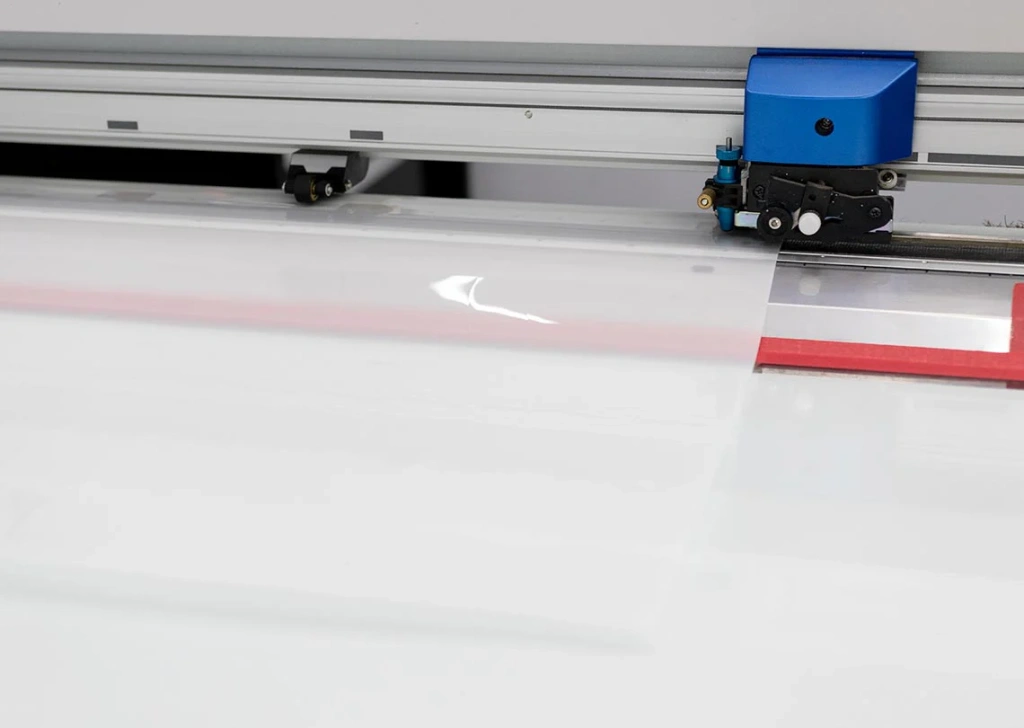

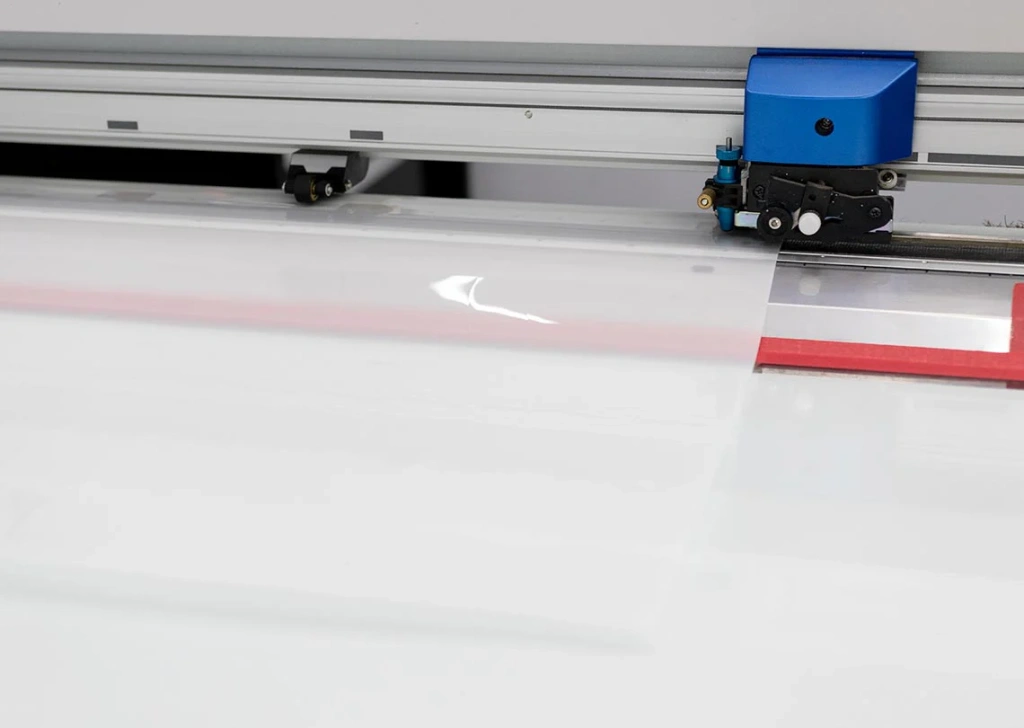

There are different styles of installation of PPF. Installation with a plotter can be done using software designed to create a pattern to the shape of the panel the film is being installed on. It is possible to modify a plotter software pattern to suit the needs of an installer and/or their customer. The most experienced installers can actually hand template panels, and then convert those templates into digital format for software to then cut them digitally, meaning that any custom work can be converted into a digital template. Installation without a plotter, by bulk installing film from the roll, is a risk, as the film is cut directly onto the surface of the vehicle.

In addition to installations performed in situ at the factory or by certified shops and dealerships, there are also a select number of vendors who sell pre-cut and vehicle specific paint protection kits, as well as individuals who sell these kits on online auction sites or other markets.